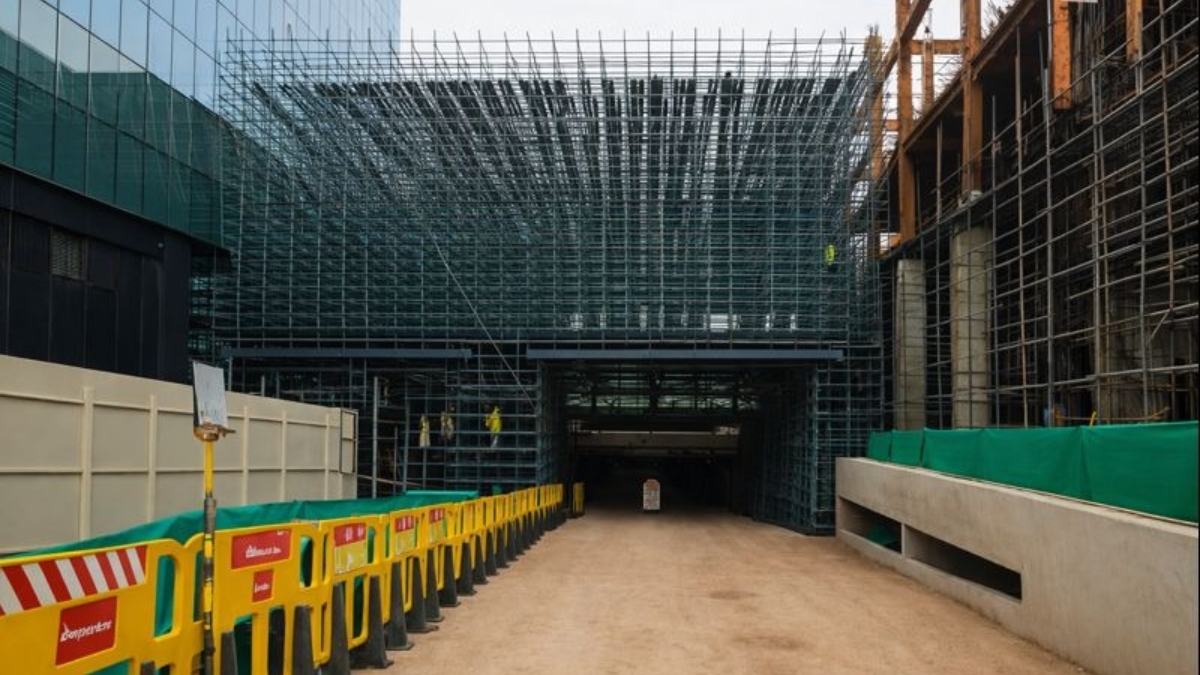

New Delhi [India], December 18: Scaffolding has always been an essential part of construction, providing temporary support and access for workers as structures rise. But as India’s infrastructure projects grow in scale and complexity, the expectations from scaffolding systems have increased dramatically. Today’s projects demand solutions that are not only strong and reliable but also quicker to assemble, easier to adapt, and safer to use. This shift has given rise to what the industry now calls smart scaffolding, systems designed with engineering precision, modular efficiency, and safety-led design.

Translite has emerged as one of the companies contributing strongly to this shift. Through engineered scaffolding systems, detailed design support, and high-quality fabrication, the company is helping modern construction sites achieve safer and faster execution across metro, highway, and industrial projects.

Understanding the Need for Smarter Scaffolding

The demands on scaffolding today are very different from what they were a decade ago. Metro corridors, elevated highways, large industrial facilities, and high piers all require systems that can handle heavy loads while being assembled within tight timelines. Traditional methods that were once dependable are no longer sufficient for projects that operate with continuous deadlines and high safety expectations.

Modern construction sites also require greater precision. Elevated structures must maintain alignment, heavy concrete loads must be supported evenly, and workers must have stable access at various heights. This has created a need for scaffolding systems that are engineered, standardised, and adaptable. Smart scaffolding answers this need by bringing design accuracy, modularity, and strong material consistency together.

Translite’s Move Toward Engineered Scaffolding

Translite’s scaffolding systems reflect this new direction in the industry. The company manufactures and supplies Cuplock and Ringlock systems, and also designs and manufactures H Frame scaffolding and Kwik Stage scaffolding to support the diverse needs of housing developments and oil and natural gas sector projects. In projects where speed and safety matter equally, having repeatable and uniform scaffolding elements can significantly reduce errors on site.

Ringlock systems supplied by Translite use a 48.30 mm tube diameter and 500 mm ring spacing. These measurements are crucial because they help distribute loads evenly and provide consistent alignment. The systems are available in a range of heights and thicknesses, allowing contractors to choose configurations that match the demands of their specific structure.

By focusing on precision manufacturing and standardisation, Translite allows construction teams to assemble scaffolding faster without compromising stability. Faster assembly means fewer delays, which is especially important in high-traffic project sites such as metros, expressways, and industrial plants.

Design, Planning, and Load Calculations

What sets modern scaffolding apart from traditional systems is the amount of engineering that goes into planning it. At Translite, the process begins with a design and engineering review of the structure that will be supported. The company’s in-house team prepares formwork and scaffolding layouts, conducts load calculations, and creates project-specific design documentation.

This design-led approach is important for structures such as:

- Piers

- Pier caps

- U, I, T, and Box girders

- Elevated highway sections

- Metro viaducts

- Industrial staging and platforms

By understanding load paths, geometry, and working conditions in advance, Translite ensures the scaffolding behaves predictably once installed. This reduces the chances of on-site adjustments and helps maintain safety throughout the project.

Smart Materials and High-Quality Fabrication

Another key element of smart scaffolding is the material used. The systems must be strong enough to withstand load variations yet easy enough to transport and handle. Translite uses high-quality mild steel in its scaffolding components and fabricates them in compliance with standards such as ISO 9001:2015, IS 1161, and IS 2062.

These standards ensure that every component, whether it is a ledger, a vertical pipe, a base jack, or a coupler, is manufactured with consistency. Uniformity is essential because scaffolding acts as a single system, and any variation in material quality can affect performance.

In industrial and infrastructure projects, where components are reused multiple times, durability also becomes part of the smart scaffolding approach. Translite’s fabrication methods support this long-term reuse, making the systems practical for contractors who work across several project sites.

Faster Assembly Through Modularity

One of the major advantages of smart scaffolding is modular design. Instead of using components that require complex adjustments or specialised tools, modular scaffolding relies on parts that connect quickly and easily.

At Translite, Cuplock and Ringlock systems are examples of this principle, and the addition of H Frame and Kwik Stage scaffolding further expands this adaptability across housing and industrial applications. Modular components also make it easier to work on structures of varying heights and shapes, something that is especially important in India’s large network of elevated metros and highways.

The ability to adjust, scale, and reposition scaffolding without needing entirely new systems makes modular scaffolding both cost-effective and time-efficient.

Safety Built Into the System

Safety is one of the most important outcomes of smart scaffolding. As construction grows taller and more complex, ensuring stable access becomes critical. Translite’s systems support safety through:

- Standardised and predictable load behaviour

- Stable walkway planks and platforms

- Strong connection points

- Rigid vertical and horizontal alignments

Additionally, precise fabrication helps reduce unexpected movements or shifts once the system is under load. When workers can rely on stable staging, productivity improves and risks are reduced.

For elevated work such as pier caps and metro viaducts, having dependable scaffolding is essential. Any instability can impact both worker safety and the quality of concrete structures.

Supporting India’s Infrastructure Expansion

Smart scaffolding plays a direct role in India’s infrastructure growth. Translite’s presence across metro projects including Delhi, Indore, Patna, and Pune demonstrates how engineered scaffolding supports safe and efficient construction at scale. The company also contributes to major expressways such as the Dwarka Expressway and the Ganga Expressway, where elevated structures rely on strong staging and shuttering systems.

In industrial sectors, Translite supports developments such as Micron Industry, Tata Power, Hyundai Corporate Office, Haier Industry, and newly added projects including Microsoft Campus in Noida, Hindustan Zinc Factory in Rajasthan, and Hindalco Factory in Odisha. These projects require heavy-duty and adaptable scaffolding platforms for maintenance, assembly, and structural works.

The widespread use of engineered scaffolding across different project categories indicates how essential it has become for India’s construction timelines.

Looking Ahead: The Future of Smart Scaffolding

Smart scaffolding will continue to advance as construction needs evolve. Engineering precision, modularity, material strength, and safety features will remain central to future systems. Design-led planning and adherence to quality standards will also become even more important as India builds larger and more complex structures. Companies like Translite, which combine design expertise with high-quality manufacturing, will continue to contribute to this shift. Their systems help create reliable working platforms that support the pace and scale of modern infrastructure. As construction demands rise, smart scaffolding will remain one of the essential tools that keeps project timelines on track and workers safe.